In manufacturing, speed is of the essence. However, many leaders find themselves spending more time addressing administrative delays than enhancing production processes.

When support tasks accumulate, growth can stall. Outsourcing can streamline these tasks, allowing you to focus on what really matters: creating high-quality products and delivering them on time.

In this guide, we will define outsourcing in the manufacturing industry, explain its benefits, and show how to implement it effectively in your business.

What Does Outsourcing Manufacturing Mean?

Outsourcing manufacturing means delegating specific production or support processes to third-party providers. While many companies traditionally outsource physical production, the current landscape of outsourcing extends beyond the factory floor. More manufacturers now outsource crucial back-office and customer-facing tasks, including:

- Order processing

- Inventory tracking

- Production documentation

- Customer support

- Compliance and quality documentation

- Technical support

- Finance and administrative workflows

How BPO Services Enhance the Manufacturing Industry

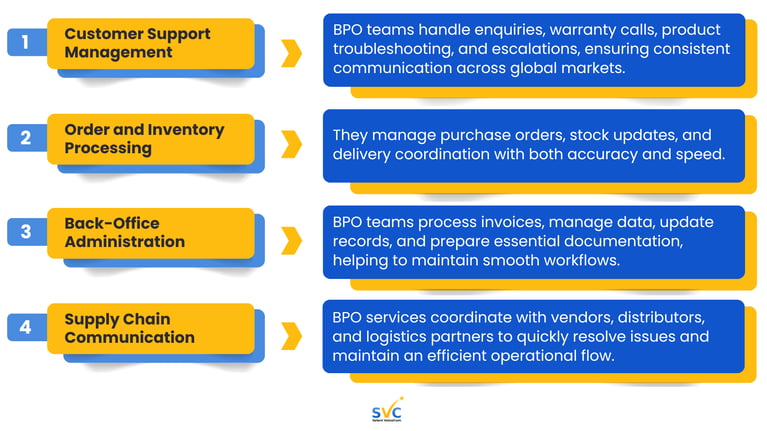

Business Process Outsourcing (BPO) has become a strategic advantage for manufacturers, helping them manage the increasing complexity of operations. Here are several ways BPO providers strengthen manufacturing processes:

This support allows manufacturing teams to focus on their production strategy and foster strong relationships with customers and suppliers.

Key Industries That Outsource Manufacturing Support Functions

The trend of outsourcing administrative and customer-facing tasks is evident across various manufacturing sectors. The industries that are leading this trend include:

- Electronics and Consumer Devices

- Automotive and Mobility

- Fashion, Apparel, and Retail Manufacturing

- Industrial Equipment and Machinery

- Food and Beverage Manufacturing

This trend is transforming global supply chains, particularly in industries such as electronics, automotive, and fashion, where adequate administrative support is vital to meeting demand and minimising downtime.

Benefits of Outsourcing Manufacturing

Manufacturers that embrace outsourcing gain benefits that extend well beyond cost savings. Key benefits include:

1. Greater Operational Efficiency

By delegating administrative tasks, companies can eliminate bottlenecks and maintain production timelines.

2. Lower Labour and and Overhead Costs

Outsourcing reduces the need for additional office staff, equipment, or infrastructure.

3. Faster Scaling

Outsourced teams can quickly adapt during peak seasons or new product launches, avoiding lengthy hiring processes.

4. Improved Quality and Accuracy

Specialised teams use structured processes to minimise errors in documentation, order handling, and customer communication.

5. Stronger Customer Experience

Trained agents provide prompt and consistent support across multiple channels, enhancing your brand's reliability.

How to Integrate Outsourcing Into Your Manufacturing Operations

Successful outsourcing begins with clarity and a well-structured plan. The following steps can help you reduce risk and establish partnerships that enhance daily operations.

1. Identify Your Pain Points

Determine where delays or inefficiencies occur, whether in order processing, documentation, or customer communication. Identifying these areas reveals where outsourced support can lead to quick improvements.

2. Define the Tasks to Outsource

Delegate processes that do not compromise compliance or quality. Focus on assigning repetitive or time-consuming tasks that distract your team from core production activities.

3. Choose a Provider with Manufacturing Expertise

Partner with a provider who understands manufacturing workflows, terminology, and standards. Industry experience ensures smoother onboarding and minimises operational errors.

4. Align on Processes and KPIs

Establish clear execution steps and determine how you will measure success. Set specific Key Performance Indicators (KPIs) and communication guidelines to ensure both teams align from day one.

5. Integrate Technology Smoothly

Ensure your partner can work with your platforms, such as your CRM (Customer Relationship Management), ERP (Enterprise Resource Planning), inventory systems, and communication tools. Seamless integration maintains visibility and prevents workflow disruptions.

6. Start Lean Then Scale

Begin with a small set of tasks, refine the process, and expand once the partnership proves effective. This approach minimises risk while enhancing long-term efficiency.

When you implement outsourcing correctly, it strengthens your manufacturing strategy, not replaces it.

Mastering Manufacturing Outsourcing: Choosing the Right Partner

Selecting the right outsourcing partner is crucial, as they should seamlessly integrate with your internal team. When evaluating potential providers, consider the following key factors:

1. Industry Experience

Look for a partner with a proven track record in manufacturing workflows and an understanding of customer expectations.

2. Scalable Teams

Ensure they can support you during peak seasons or high-volume orders.

3. Advanced Technology

Seek providers that utilise modern technology, such as CRM systems, workflow automation, and data analytics.

4. Data Security

Verify that they comply with essential security standards, including PCI DSS, SOC2, ISO 27002, and GDPR.

5. Cultural Alignment

Choose a partner whose communication style aligns with your company's culture to maintain consistency and brand integrity.

6. Training Programmes

Ensure their training process equips teams to deliver accurate, consistent service that supports your manufacturing workflows.

Choosing the right partner helps you achieve long-term efficiency rather than merely focusing on short-term cost savings.

FAQS about Outsourcing Manufacturing for Your Business

1. How do you outsource manufacturing?

You outsource manufacturing by identifying which tasks slow down your operation and delegating them to a qualified external partner. A structured plan that covers processes, KPIs, training, and technology ensures a smooth and effective transition.

2. What is an example of outsourcing manufacturing?

Common examples include outsourcing order processing, inventory tracking, customer support, and technical troubleshooting to a BPO provider. These functions help manufacturers improve speed and accuracy without expanding internal headcount.

3. What Should I outsource in my business?

Manufacturers typically outsource time-consuming, repetitive, or support-focused tasks such as documentation, compliance reporting, administrative workflows, and customer service. These areas deliver fast efficiency gains without compromising core production.

4. What are the risks involved in outsourcing?

Risks include misalignment in communication, inconsistent quality, or data security concerns if the provider lacks proper standards. Choosing an experienced, compliant partner with strong onboarding processes minimises these risks.

5. What is it called when you outsource manufacturing?

Outsourcing manufacturing is commonly referred to as manufacturing outsourcing or contract manufacturing, especially when it involves production. When delegating support or administrative tasks, it falls under BPO for manufacturing.

Scale Smartly and Sustainably with Select VoiceCom

Select VoiceCom (SVC) provides manufacturers with administrative, customer support, and back-office teams that strengthen operational scalability. With nearly two decades of experience in the BPO industry, we know the importance of reliable support for your success.

Our teams in Cebu and Davao, Philippines, deliver professionalism, speed, and a deep understanding of global manufacturing needs. Whether you need order management, technical support, documentation processing, or 24/7 customer service, SVC has the expertise to help you operate confidently.

Ready to elevate your manufacturing operations? Contact SVC today and let us help you create a more innovative workflow for your business.

More Articles Like This

Why Growing Brands Need Ecommerce Customer Service Outsourcing

As your e-commerce brand grows, the demand for quick and reliable support increases. However, small teams often struggle to meet these rising expectations independently. Customer service outsourcing for e-commerce gives you trained experts and scalable support, ensuring that growth never compromises the customer experience.

.jpg)

7 Proven Ways to Streamline Business Processes and Boost Efficiency

In pursuing growth, efficiency stands out as your most valuable advantage. Understanding how to streamline business processes allows your organization to stay agile, productive, and competitive in an ever-evolving market.

.jpg)

How to Scale a Business with the Help of a Call Center Partner

Knowing how to scale a business is one of the biggest challenges companies face as they expand their operations. Many businesses respond by hiring more staff or investing in infrastructure.